AUTOMATE AND OPTIMISE YOUR WAREHOUSE WITH ROBOTS.

Whether lifting, pulling, or pushing, our AMRs effectively manage a variety of internal transport tasks within your warehouse, optimising your operations and enhancing efficiency.

ABOUT BOWE MOVE.

BRIDGING THE GAP BETWEEN DYNAMISM & AUTOMATION WITH AUTOMATED WAREHOUSE ROBOTS.

Increasing order volumes, time constraints, staff shortages, and complex logistics processes pose significant challenges today. Our intelligent autonomous mobile robots (AMRs) can optimise your operations and enhance efficiency. Whether lifting, pulling, or pushing, our AMRs effectively manage a variety of tasks within your warehouse. Furthermore, our innovative software ensures seamless integration with your systems, providing you with complete visibility of your material flow at all times.

Whether in manufacturing, warehousing or shipping – our AMRs are the perfect solution for a wide range of applications. Feel free to get in touch by submitting our contact form.

HOW CAN WE HELP YOU?

BOWE MOVE’S INTELLIGENT AMRs.

WAREHOUSE-READY AMRs, ADAPTING TO YOUR EVERY LAYOUT.

Our AMRs (autonomous mobile robots) are more than just transport robots – they are intelligent assistants optimising your processes. Equipped with state-of-the-art sensor technology and our intuitive software MOV.ai, they navigate safely and precisely through your production halls without needing fixed paths. Thanks to the flexible deployment options, they can effortlessly adapt to changing environments and production requirements. Whether you’re shifting full pallet loads or carefully staging individual items overnight, our AMRs meet every task head-on.

BOWE MOVE offers innovative solutions to automate your internal transportation process.

PALLETBOT.

Transport and lift pallets, mesh containers, or water tanks up to 1.3m high with east. The PalletBot delivers your goods exactly where they are needed.

FLEXXBOT.

With its flexible gripper arm and a maximum payload of 1,000kg, the FlexxBot is up for any challenge. Navigating your production environment safely and reliably.

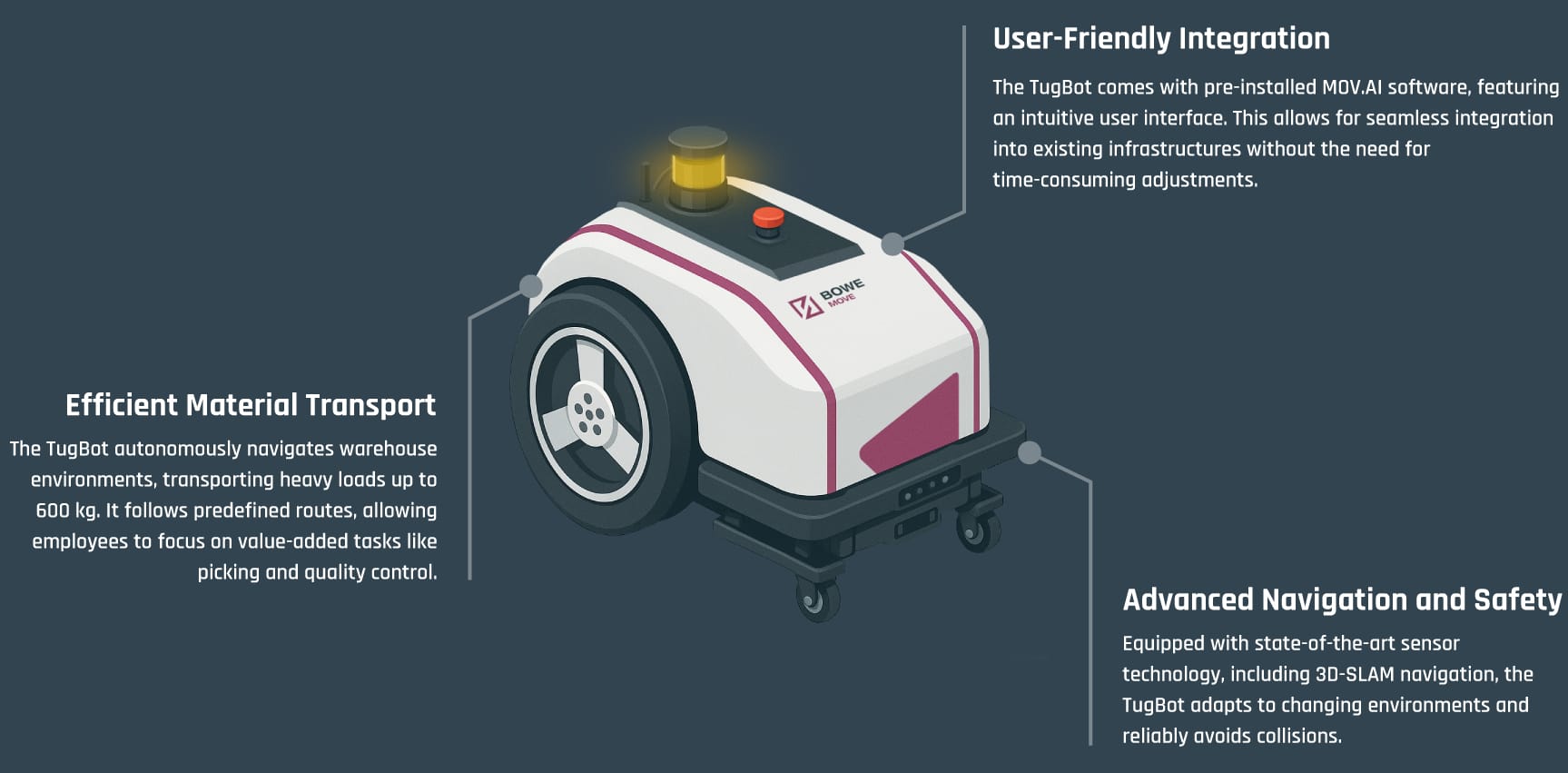

TUGBOT.

Small, agile and capable of pulling almost any cart, the TugBot is the all-rounder in the warehouse.

MOV.AI-OS.

Benefit from smart AMRs powered by an advanced operating system. Our operating system enables precise navigation based on 3D-Slam through sensor data evaluation, flexible object recognition, and autonomous route planning.

IMPROVE YOUR WAREHOUSE LOGISTICS!

MORE THAN JUST TRANSPORT ROBOTS: YOUR TRUSTED PARTNERS IN LOGISTICS.

OPTIMISE COMPLEX PROCESSES.

Optimise warehouse processes and increase productivity across your warehouse through the implementation of AMR’s.

REDUCE RISK OF EMPLOYEE INJURY.

Remove any monotonous, physically demanding and potentially dangerous tasks for your team, and reduce the potential of workplace injuries.

MOV.AI INTEGRATION.

Whether in logistics, manufacturing, healthcare, or retail, MOV.AI provides you with the ability to control all of your fleet using the intuitive user interface.

REDUCED DOWNTIME.

With small charging times, ranging from 20-25 minutes to 2 hours, enables an operating time of up to 8 hours – for maximum productivity without interruptions.

EFFICIENT ROBOTICS FOR SEAMLESS LOGISTICS.

BOWE MOVE DELIVERS FAST, ACCURATE, EFFICIENT AMR LOGISTICS SOLUTIONS.

Discover how AMRs (autonomous mobile robots) can enhance your operations. Your internal logistics can benefit from:

Automating Repetitive TasksIncreased EfficiencyFlexibilityOptimised Material FlowFlexibility for Peak OrdersSafetyAccident ReductionFlexibility for Peak OrdersProcess ReliabilityLower Personnel Costs