Warehouse operations are evolving at pace. Rising order volumes, labour shortages and the demand for faster, more accurate fulfilment have made automation a strategic priority rather than a long-term ambition.

At the centre of this shift are types of warehouse robots, each designed to support specific tasks within the wider intralogistics environment.

This guide explores the types of warehouse robots, explains how each robot works, highlights where they fit within broader types of warehouse automation, and helps you understand how to choose the right solution for your operation. We’ll also look at how BOWE Group UK & Ireland integrates robotics into scalable, future-ready warehouse automation strategies.

Why Warehouse Robotics Are Transforming Intralogistics

Warehouse robotics are no longer reserved for global eCommerce giants. Today, businesses of all sizes are adopting robotics as part of flexible, modular types of warehouse automation that improve efficiency without requiring full site redesigns.

Robots support intralogistics by:

- Reducing manual handling and repetitive tasks

- Increasing throughput and operational predictability

- Improving safety and accuracy

- Enabling 24/7 operations

- Supporting scalable automation as demand grows

Understanding the different warehouse robots types available is the first step toward building a successful automation strategy.

The Main Types of Warehouse Robots

There are several core types of warehouse robots, each suited to different workflows, layouts and automation goals.

Autonomous Mobile Robots (AMRs)

Autonomous Mobile Robots (AMRs) are among the most flexible warehouse robots types. They navigate independently using sensors, cameras and onboard intelligence, adapting in real time to obstacles and layout changes.

Read more

How AMRs work

- Use SLAM (Simultaneous Localisation and Mapping)

- Move dynamically without fixed routes

- Integrate with WMS/WCS software

Where they fit in warehouse automation

AMRs are ideal for transport tasks, putaway, replenishment and station-to-station movement. They form a key component of modern types of warehouse automation that prioritise scalability and flexibility.

Automated Guided Vehicles (AGVs)

AGVs are a more traditional form of warehouse robotics, operating along predefined paths such as wires, magnets or reflectors.

Read more

How AGVs work

- Follow fixed guidance routes

- Perform repetitive, predictable movements

- Require controlled environments

Where they fit in warehouse automation

AGVs suit high-volume, stable processes where routes rarely change. They remain relevant in certain warehouse robots types, particularly in production-linked logistics.

Robotic Arms & Articulated Pickers

Robotic arms handle precise picking, placing and packing tasks, often combined with vision systems and AI.

Read more

How robotic arms work

- Use multi-axis articulation

- Identify items using cameras and sensors

- Execute repetitive pick-and-place actions

Where they fit in warehouse automation

These robots are central to picking, packing and kitting processes and integrate into advanced types of warehouse automation focused on accuracy and speed.

Goods-to-Person (G2P) Robotic Systems

G2P systems use robots to bring goods directly to operators rather than sending staff to walk the warehouse.

Read more

How G2P systems work

- Robots retrieve storage units or totes

- Deliver items to ergonomic picking stations

- Reduce walking time and labour fatigue

Where they fit in warehouse automation

G2P is one of the most impactful warehouse robots types for order fulfilment-heavy operations, forming a core pillar of high-density types of warehouse automation.

Sorting Robots

Sorting robots automate the identification and distribution of items across conveyors, chutes or destinations.

Read more

How sorting robots work

- Use barcode or vision scanning

- Automatically divert items at speed

- Integrate with warehouse control systems

Where they fit in warehouse automation

They support outbound logistics, parcel handling and distribution centres, strengthening overall types of warehouse automation.

Inventory & Inspection Drones

Drones provide a unique approach to inventory management and inspection tasks.

Read more

How drones work

- Fly autonomously within warehouse aisles

- Scan barcodes or RFID tags

- Feed data directly into inventory systems

Where they fit in warehouse automation

These warehouse robots types support inventory accuracy and safety audits, complementing larger automation frameworks.

Forklift & Pallet-Handling Robots

Pallet-handling robots automate heavy load movement traditionally performed by forklifts.

Read more

How pallet robots work

- Transport full pallets autonomously

- Navigate safely around people and equipment

- Operate continuously with minimal supervision

Where they fit in warehouse automation

They replace repetitive forklift tasks and are increasingly popular within flexible types of warehouse automation strategies.

How to Choose the Right Type of Warehouse Robot

Choosing between different types of warehouse robots depends on several factors:

- Warehouse layout and available space

- Order profiles and throughput requirements

- Level of process variability

- Integration with existing WMS/WCS software

- Scalability and future growth plans

Rather than selecting a single robot, many businesses combine multiple warehouse robots types within layered types of warehouse automation to create end-to-end efficiency.

Industries Taking Advantage of Warehouse Robots

Warehouse robotics are now widely adopted across:

- eCommerce and retail fulfilment

- Manufacturing and production logistics

- Food and beverage distribution

- Pharmaceuticals and healthcare

- Parcel and postal operations

Each industry applies different types of warehouse robots depending on product handling, speed and compliance requirements.

Where BOWE Fits Into Warehouse Robotics

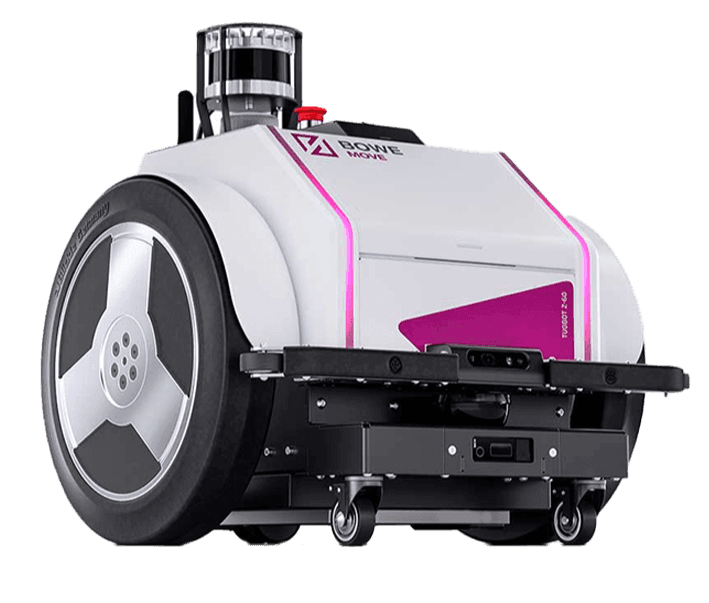

- Autonomous mobile robots for transport and replenishment

- Pallet-handling robots for heavy-load automation

- Software-driven orchestration through intelligent control platforms

- End-to-end system design covering inbound to outbound flows

Rather than standalone robotics, BOWE focuses on integrated warehouse robots types that work in harmony with software, conveyors and storage technologies.

Future Trends in Warehouse Automation & Robotics

The future of warehouse automation is increasingly intelligent and interconnected. Key trends include:

- AI-driven robot decision-making

- Greater interoperability between robot fleets

- Increased adoption of modular types of warehouse automation

- Software-led optimisation and analytics

- Rapid scalability without infrastructure overhaul

As these trends accelerate, understanding the right types of warehouse robots becomes essential for staying competitive.

The main types of warehouse robots include AMRs, AGVs, robotic arms, goods-to-person systems, sorting robots, drones and pallet-handling robots.

AMRs navigate dynamically using sensors and AI, while AGVs follow fixed routes. AMRs offer greater flexibility within modern types of warehouse automation.

Goods-to-person systems and robotic picking arms are among the most effective warehouse robots types for fulfilment operations.

Robots integrate with WMS and WCS software, forming part of connected types of warehouse automation that manage workflows end to end.

Yes. Many types of warehouse robots are modular and scalable, making them ideal for SMEs looking to automate incrementally.

Warehouse robots typically require fleet management software, WMS/WCS integration and real-time monitoring platforms to function effectively.